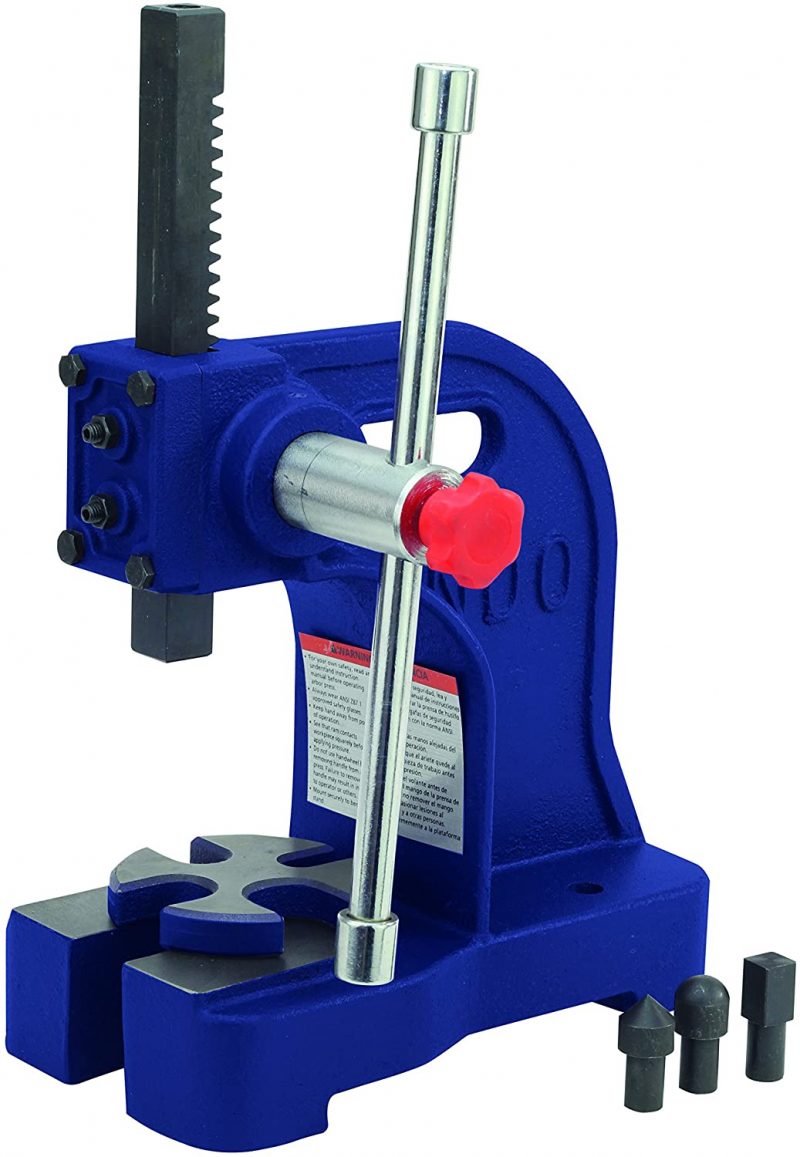

A majority of the people consider the arbor press to be a small tool that is not much useful. However, this is far away from reality.

The process of jewelry making is time-consuming and needs acute precision in every detail added to the piece. The process requires manual labor, and arbor presses are often put to use for various tasks. Pick the best one for jewelry making. A high-quality press will prove effective and work wonders. You will be able to make cuts and other details to your pieces precisely. A great manual arbor hand press will prove beneficial. Also, they will assist in saving a lot of time and money.

Arbor press can be utilized for embossing, embedding patterns, or making holes.

Buy a decent working arbor press so that you don’t have to worry about making wrong cuts and dealing with hampered designs. You can work on various jewelry and other similar accessories that include necklaces, earrings, bracelets, rings, etc. A manual press can assist in speeding up the production and, at the same time, maximizing time and profits. With it, effortlessly stamp designs and shapes to your collection or any other metal. Position the material in the machine and pull its lever.Â

Find the best choices of arbor presses available in the market to choose from. We have listed good picks based on intense market research to assure that our readers get only the best.

Table of Contents

- 1 Top 10 Arbor Press For Jewelry Making USA

- 1.1 Jet 333605 Arbor Press

- 1.2 Dake 00 Single Model Leverage Arbor PressÂ

- 1.3

- 1.4 Central Machinery One Ton Arbor Press

- 1.5 HHIP 8600-0031 Heavy Duty Arbor Press

- 1.6 Palmgren AP10 Manual Arbor Press

- 1.7 PanaVise 502 Precision PanaPress

- 1.8 HHIP 8600-0131 Arbor Press

- 1.9 Palmgren AP05 0.5 ton Arbor Press

- 1.10 HHIP 8600-0032 Heavy-duty Arbor Press

- 1.11 Klutch 1 ton Arbor Press

- 2 Arbor Press For Jewelry Making USA Buying Guide

- 3 Frequently Asked Questions (FAQs)

- 3.1 How many types of arbor presses are there?

- 3.2 How many parts does a single leverage arbor press have? Discuss the functions of each piece?

- 3.3 How much tonnage does an arbor press need?

- 3.4 How should a single lever press be used?

- 3.5 How is the ratchet press used?

- 3.6 Why is a compound leverage press used?

- 4 Conclusion

Top 10 Arbor Press For Jewelry Making USA

Jet 333605 Arbor Press

Jet is a very famous brand that deals in tools manufacturing. The Jet 333605 Arbor is a heavy and ductile cast iron-made arbor press that delivers a maximum of 0.5 tons of maximum working pressure. You get a two-year warranty period on the Jet 333605 arbor press, making it a highly reliable option.

Within the warranty period, you can also avail of free-cost repair service from the Jet’s authorized service centers.

The maximum height capacity on Jet 333605 is four and ¾ inches, and its maximum supported work diameter is six … inches. It allows multiple operations to be done simultaneously, and the anvil available on the Jet 333605 Arbor Press has four slots.

Features

- Number of anvil slots- 4

- Weight- 19 lbs

- Maximum height capacity- 4 ¾ inch

- Maximum supported diameter- 6 … inches

- Ram Face Area- ¾ × seven …

- Warranty Period- Two Years

- Maximum Working Pressure- ½ Ton

- Heavy ductile cast iron body

[/i2pros][i2cons]Maximum working pressure is very low

The maximum working height is comparatively lower.[/i2cons][/i2pc]

Dake 00 Single Model Leverage Arbor Press

Dake manufactures many top-tier production equipment and machines, including an arbor press.

Dake 00 Single leverage arbor press is made of grey cast iron with 1 square inch ram and weights one-ton. You can get several tasks done with it, such as pressing, removal, installation, etc. as the pressure is very high. It consists of a dual-direction adjustable handle that operates the ram with a 25:1 ratio. The Dake 00 Model Single Leverage Arbor Press base has holes for installation on higher surfaces like workbenches and tables.

The maximum working diameter on the Dake 00 Single Model Leverage arbor press is 7 inches, whereas the maximum working height available is 5 inches. Dake 00 Single Model Leverage Arbor Press is a wise option to carry around on jobs due to its comparatively lower weight (25 lbs) than other arbor presses on this list. This arbor press’s ram is made out of case hardened steel, which is a better option than cast iron.

Features

- Case hardened steel ram

- Weight- 25 lbs

- Working Diameter- 7 inches

- Maximum Working Height- 5 inches

- Mounting Holes

- Lever ratio of 25:1

- Dual direction adjustable handle

- Grey cast iron body

- Maximum Pressure- One-ton

Great Build Quality

[/i2pros][i2cons]Maximum working height is very low

Mounting is necessary [/i2cons][/i2pc]

Central Machinery One Ton Arbor Press

Central Machinery is a famous brand which is known for its durable production tools. Fortunately, they also manufacture arbor press along with other tools.

We are showcasing Central Machinery One-ton arbor press at the third position. Considering its low price tag, this arbor press offers a lot of features.

The weight of the Central Machinery One-ton Arbor Press is 34.6 lbs, and its body is made of cast iron. But still, this is a very durable arbor press. The formation of rust on the surface is prevented in a humid environment due to an anti-rust coating.

The maximum pressure capacity of 1 ton can be applied over a square inch surface area. Such an amount of pressure is more than enough for any basic application of an arbor press. An adjustable 20:1 ratio lever operates central Machinery One Ton Arbor Press. To reduce the input force, you can adjust the length of the lever on either side.

Features

- Mounting Holes

- Adjustable Lever

- 20:1 Lever ratio

- Ram Area- 1 Square Inch

- Anti-rust coating

- Weight- 34.6 lbs

- Cast iron body

- Comparatively cheaper arbor press

- Maximum Pressure Capacity- One Ton

Decent budget arbor press

[/i2pros][i2cons]Maximum working height is comparatively low

Heavy[/i2cons][/i2pc]

HHIP 8600-0031 Heavy Duty Arbor Press

In the fourth position, we have an arbor press from the brand HHIP. This brand manufactures several production tools and related small products, alongside the arbor press.

HHIP 8600-0031 has a solid heavy-duty cast iron body, but it weighs only 24 lbs. You get 10 inches of arbor press height with HHIP 8600-0031, as height is a very important aspect for an arbor press. It can also deliver ½ ton pressure on the workpiece.

The anvil has four different ports where one port is 1.69 inches deep and 1.02 inches wide, and three ports are 1.38 inches deep and 0.55 inch wide. This variation in the sizes of the ports allows clamping of different sized materials.

The ram available is ¾ inches and is made up of steel. This ram is operated by a pinion and rack mechanism with an adjustable lever. The base size available on this arbor press is four — 9 inches. You can comfortably use up to 6.5 inches diameter workpiece with this arbor press. You can get several operations like riveting, squeezing, punching, etc. done with it.

Features

- Adjustable lever

- Maximum Work Diameter- 6.5 inch

- Ram of ¾ inch made of steel

- Base size- 4 inches × 9 inches

- Number of anvil ports- 4 (1 Bigger Port)

- Pressure Capacity- ½ Ton

- Arbor Press Height- 10 inches

- Lightweight

- Heavy-duty cast iron body

Heavy-duty body

[/i2pros][i2cons]Mounting required before using

The maximum working pressure is comparatively low.[/i2cons][/i2pc]

Palmgren AP10 Manual Arbor Press

Palmgren makes several tools such as quick release vise, machine vise, an arbor press, etc. along with supporting equipment.

Palmgren AP10 manual arbor press has a strong cast iron body along with many great features. You can apply up to one Ton of pressure on the workpiece with Palmgren AP10. It also has a four-port anvil, which will allow you to carry out four different operations at once. The special feature of the Palmgren AP10 Arbor Press is the optional circular handle, with the help of which you can operate it quite easily compared to other arbor presses.

If you wish to use the lever instead of the circular handle, you also get a lever with an 18:1 ratio. This arbor press’s overall height is 11 inches, whereas the maximum working height available is 6 inches. The base of the Palmgren AP10 provides strong support to the structure and is 1 ¹/16 inches long and six â…› inches wide. The overall weight of the Palmgren AP10 Manual arbor press is 34 lbs.

Features

- Weight- 34 lbs

- Base Area- 6 …› — one ¹/16 inches

- Height of the arbor press- 11 inches

- Maximum Working Height- 6 inchesÂ

- 18:1 lever ratio

- Optional circular handle

- Easy to operate

- Number of anvil ports- 4

- Maximum Working Pressure- One Ton

- Cast iron body

Decent build quality

[/i2pros][i2cons]A bit expensive than other arbor presses

Comparatively heavy[/i2cons][/i2pc]

PanaVise 502 Precision PanaPress

This arbor press features a ¼ ton of pressure that makes it fit for general and industrial repairs and tooling. The PanaVise 502 Precision PanaPress also features a reversible ram that applies up to ¼ Ton and 500 lbs of pressure, thus balancing its application with the power.

The PanaVise 502 Precision PanaPress is also designed with a ram that has 0.251″ reaming on one end to add tooling. You can also enjoy exceptional ram control with four adjustable nylon Gibbs. The Gibbs also allows the user to make accurate and precise adjustments with minimal play.

The arbor press is also designed with a base footprint of 94 mm — 177.8 mm (3.7″ — 7″) and four countersunk holes at the corner. Such features allow for comfortable bolting of the product to a work surface. The product also has two extra tapped and pre-drilled holes, which eases the process of mounting retrofit kits on the base.

FeaturesÂ

- Power Source: Hand-operated (Manual)

- Maximum Working Load: 500 lbs

- Ram- ¼.”

- Maximum Pressure Height- 8

- Maximum Diameter: 5 –

- Press: ¼ ton press

- Pinion and rack-driven reversible ram

- Compact arbor press

- Silver anodized cast-iron housing

- Adjustable nylon gibs

- Reversible ram

- Countersunk bolting holes

Durable anodized cast-iron finish

Sturdy and compact design

Versatility

[/i2pros][i2cons]Fit for only medium to light-duty pressing[/i2cons][/i2pc]

HHIP 8600-0131 Arbor Press

HHIP is one of the most popular best tool-making companies dominating the market with their best lineup of arbor presses for jewelry making. HHIP manufactured model 8600-0131 arbor press has a cast iron made from the grained body to take care of your hardest tasks. The body of HHIP 8600-0131 also features a special coating that helps it to fight against rust. It can take one Ton of pressure and comes with a removable anvil that sits at the arbor’s bottom. Its unique anvil has four slot positions for smooth operation and accurate/precise measurements.

It can be used for riveting, bending, squeezing, punching, and other pressing operations. The steel ram attached to the anvil is rugged as the body of the HHIP 8600-0131 arbor press.

FeaturesÂ

- Its maximum Height Capacity is 14 inches, which is sufficient to take care of a fat working pieceÂ

The base of this arbor press comes pre-drilled for mounting on the pedestal, reducing vibration

Enough power was provided to handle several tasks by putting low pressure on the attached rounded handle and the handle of the arbor press

Extra circular handle provided with the HHIP 8600-0131 Arbor Press

[/i2pros][i2cons]Customers have complained about damaged parts.[/i2cons][/i2pc]

Palmgren AP05 0.5 ton Arbor Press

The Palmgren AP05 0.5 ton arbor press can be used for a wide range of professional and DIY tasks like riveting, bending, and punching. It is designed to guarantee versatility with compact designs that allow for easy portability.

The tool features a solid cast-iron housing that protects it from corrosion when used in a bad environment. Even though the Palmgren AP05 0.5 ton arbor press is a manual press, it is designed with a hydraulic steel r to exert the needed pressure per application.

Since this arbor press allows for magnetic insertion on one end of the ram, the addition of other punches and tools is made easy for it. The product also features a pre-drilled base that makes for easy mounting on any surface.

Features

- Power Source- Hand-operated (manual)

- Lever ratio- 18.1: 1

- Swing: 6 – ½ inches

- Maximum press height- 4 – … inches

- Maximum diameter: 3 – ½ inches

- Press: 0.5-ton press

- Steel cam locking mechanism

- The pre-drilled base for quick and easy mounting

- Removable steel anvil

- Adjusting, fined, and lockable screw

- It’s fitted with depth stops

- On one end, there is a reversible ram with a magnetic hold

Durable construction made of heavy-duty and solid cast iron

Compact design allows improved and enhanced portability

[/i2pros][i2cons]Punches usually fall out of place

When exposed to moisture or other rust agents, iron housing is prone to rust.[/i2cons][/i2pc]

HHIP 8600-0032 Heavy-duty Arbor Press

You can get finer measurements and also limit the depths to fit the application with the accurate depth limiter of the ram stroke of the HHIP 8600-0032 Heavy-duty Arbor Press. It boasts heavy-duty cast-iron housing that provides durability and strength.

It can support different workpieces due to the four position anvils with the HHIP 8600-0032 Heavy-duty Arbor Press. Its ram control is also designed to offer the user increased accuracy and a smooth operation. It can also be used for punching, squeezing, and other pressing operations as it has been designed keeping versatility in mind for multi-users.

Features

- Power Source: Hand-operated (Manual)

- Base Measurements (Length — Width): 11 inches — 5 inches

- Ram: 1 – ¼ inches

- Capacity over the table: 8 – ½ inches

- Maximum press height: 18 inches

- Maximum diameter: 12 inches

- Press: One-ton heavy-duty arbor press

- Depth limiter

- Steel pinions

- Removable anvils

- Four-position steel anvils

- Cast-iron casing

Heavy-duty cast-iron framing

[/i2pros][i2cons]Fit for only light to medium pressing duties [/i2cons][/i2pc]

Klutch 1 ton Arbor Press

Klutch 1 ton Arbor press is a precise and strong press that applies the pressure essential for removing, stamping, and seating bearings and performing other high-pressure production, repair, and assembly jobs.

The Klutch 1 ton arbor press delivers up to 1 ton of continuous force with the pull of a handle made of steel. It is made up of durable cast iron, which won’t rust easily. The Klutch 1 ton arbor press can also withstand multiple falls from your workbench without warping.

Precisely stamping every single time becomes simple due to the construction of the cast iron bar. Although Klutch isn’t a well-known or popular manufacturer, the Klutch 1 ton Arbor Press is still worth considering if you need an all-purpose and simple tool for a wide range of applications. The Klutch 1 ton Arbor Press has a maximum working height of 6 inches.

Features

- Maximum Working Height: 6 Inches

- Ram square: 1 — 1 inch

- Length of the ramp: 10 inches

- Largest arbor: 45/64 – 1 27/64 inches

- Base Area (L — W): 5 ¾ — four ¼ inches

Solid anvil surface for tough shaping and pounding tasks

Durable cast iron construction

[/i2pros][i2cons]Cost is on the higher end[/i2cons][/i2pc]

Arbor Press For Jewelry Making USA Buying Guide

Artisans need to look into multiple factors while buying an arbor press. Admittedly, nothing called the perfect arbor press exists. A 0.5 ton to 3-ton press is the best arbor tool for jewelry making. However, a home mechanic should look out for an arbor tool that is at least 3 to 5 tons or heavier. An inferior quality arbor press will hardly be helpful. So, let us find out which factors we need to look into while buying the arbor guide.

Avoid cheap imports

It is natural to get value for money. An affordable, imported arbor press will not have tight tolerance on the moving parts. The user will also not feel good while using the machine from the beginning. Accuracy may take a hit because of such factors. Accuracy is of prime importance when the tool is presented to the die. So, it is better to avoid the cheap, imported arbor tools.

Look out for a Craiglist or a salvage yard arbor press while buying an arbor press. These machines are often available at a lower cost after their owners expire, and their workshops are cleaned out. These models have better engineering and tolerance than the cheap, imported products available in the market. They will also have higher accuracy.

Availability of space

Most of the arbor presses available in the market are bench mounted. The artisans need to fix a particular area in their workspace, where the arbor press will be kept permanently. A specific space needs to be mounted first. Then, the artisans need to choose an arbor tool that fits the available space.

Suitability

Choose the most suitable arbor press tool. A piece of six-ton compound jewelry will be useless for stamping jewelry. So, people need to match the press to the type of work done. It is better to figure out what kind of arbor tool is necessary and then buy a press one or two bigger than required. The capacity of an arbor press is measured by the Ton.

Also, consider the attachments you will use while investing in an arbor press. Multiple combinations of cutters, riveters and other tools are available in all sizes and shapes to perform a host of tasks. The smiths need to be confident that the press they buy will fit the tooling they need to use. A few rams are magnetic so they may help while holding the tools. Other rams are reversible. They have a hole at the end to maintain the tooling.

Utility

A few artisans are content to do punching, cutting, and shaping manually. Such artisans do not need to buy an arbor press. On the contrary, many others prefer a machine to do the heavy lifting on their behalf. They should invest in an arbor press.

Sufficient throat space

The area between the main body and the ram is throat space. The bigger the throat space is, the larger workpiece can be fitted in the arbor press.

Build quality

Many reputed brands manufacture arbor presses. So, the arbor press’s build quality varies to a great extent, according to the brand. The build quality determines how long an artisan will use the arbor press in the future.

Working height

The working height of an arbor press indicates whether it can operate during various jobs. The driving pressure will also vary according to the available size of the arbor press.

Frequently Asked Questions (FAQs)

An arbor press is an essential tool in the field of jewelry making. It is natural for smiths to have a lot of questions in their minds about this appliance. So, let us discuss a few common questions and their answers:

How many types of arbor presses are there?

Basically, there are three types of arbor presses. They are as follows:

- Single leverage arbor press

- Ratchet leverage arbor press

- Compound leverage arbor press

How many parts does a single leverage arbor press have? Discuss the functions of each piece?

A single leverage arbor press has four parts. They are as follows:

- The handle: The handle acts as a long part of the lever while the leverage ratio is being calculated.

- The pinion: The pinion is a tiny gear. It takes the rotation of the handle and acts as a lever when the leverage ratio is calculated. The purpose of the pinion is to transform the movement into an up and down one. It rotates through the Rack or ram.

- The Rack or ram: This gear is the counterpart to the pinion. The teeth of the Rack or ram match the teeth of the pinion. Then, the pinion moves the Rack up and down. As a result, the pressing motion is created.

- The frame: The frame provides support for the entire tool. This way, it helps guide the ram.

How much tonnage does an arbor press need?

There is no fixed rule for the tonnage of an arbor press. It is next to impossible to get the rated tonnage without a cheater bar. A cheater bar is a modified, longer bar. So if some people realize that they need to give one Ton of pressure, they should invest in a 2-ton arbor press. Otherwise, they may need to hang from the handle for the entire duration of the production run. A bigger arbor press also provides more throat space. The tonnage rating is the maximum pressure that an arbor press may take before the machine collapses.

How should a single lever press be used?

A single lever press is both convenient and efficient. It has a handle fitted within a hole in the cog spindle. The users only need to pull the handle and allow the press to apply pressure. It is the simplest arbor tool.

How is the ratchet press used?

A Ratchet arbor press has a handle on the opposite end of the cog spindle. It allows the user to place the ram in an appropriate position before applying pressure with the handle. The handle is placed in the best position to apply pressure.

Why is a compound leverage press used?

The compound leverage arbor press is for heavyweight jobs. They are used for applications that need an extra feel.

Conclusion

No occasion is complete without jewelry. Irrespective of gender, people adorn themselves with jewelry when the event calls for it. So, jewelry making is a lucrative business. This business needs certain tools. An arbor tool is one such tool. Artisans use this tool to apply steady pressure on an object or to a particular area of the item.

Arbor presses are an integral part of jewelry making. The compatible, sturdy appliances are versatile. They work with precision. Their high level of accuracy makes them indispensable. We hope that this article helped you to get a complete insight into the best products. Choose an option best suited to you after following the factors mentioned here.

Best Value- Central Machinery One Ton Arbor Press

Best Choice-Â HHIP 8600-0032 Heavy-duty Arbor Press

Premium Choice-Â Â Palmgren AP10 Manual Arbor Press

2 comments