A rolling mill is a jewelry-making tool used to shape and form metals. Crafters use it to roll out sheet metal or to reduce the thickness of metal bars or rods. Rolling mills come in various sizes and can be operated manually or by power.

Jewelry makers use rolling mills for various tasks, including forming curves, drawing wire, and creating texture on metal. When using a rolling mill, you must be careful not to overwork the metal, which can lead to cracking or breaking.

A rolling mill will last for many years with proper care and use and will provide jewelers with a versatile way to create beautiful jewelry pieces. In this article, I will go over the specific features that make the best rolling mills and list 4 products that I feel cover most, if not all of the jewelry-making needs when it comes t this specific type of equipment.

Related: Best Engraving Machine for Jewelry: Top 6 Choices in 2023

Table of Contents

- 1 What are the different types of rolling mills?

- 2 What are the essential features of a Jewelry rolling mill?

- 3 Best Enntry-Level Rolling Mill for Jewelry Making

- 4 Best Premium Rolling Mill for Jewelry Making

- 5 Best Value Electric Rolling Mill for Jewelry Making

- 6 Wgwioo Jewelry Rolling Mill Machine

- 7 Rolling mill adjustable rollers

- 8 Rolling mills Q&A

- 9 What are 4 of the standard roll configurations?

- 10 What is 4 hi rolling mill?

- 11 What is cold rolling mill?

- 12 What is a triple roller mill?

- 13 What is a two-high rolling mill?

- 14 Conclusion

What are the different types of rolling mills?

There are several different rolling mills, each designed for a specific jewelry-making task. Standard rollers include flat rollers, wire rollers, and combination rollers. Flat rollers are typically used to flatten and smooth metals, while wire rollers create thin metal sheets or reduce the diameter of thicker wires.

Combination rollers can be used for both tasks, and these are the ones I think Jewelers should be using. Rolling mills vary in size and power, so choosing one that will suit your needs is essential.

- Best entry-level: Gdrasuya10 Combination Rolling Mill

- Best Premium: Durston 130mm Agile Combination Rolling Mill

- Best value electric rolling mill: PepeTools Ultra Power Electric Combination Rolling Mill

What are the essential features of a Jewelry rolling mill?

Many different types of rolling mills are available on the market, each with unique features and capabilities. When choosing a rolling mill for jewelry making, you must consider the type of metal you’ll be working with and the desired output. Some of the key features to look for in a rolling mill include:

- Rolling thin metal sheets is vital for creating delicate jewelry designs. The rolling mill I will present in this article can press as slim as 0.03mm, ideal for delicate jewelry pieces.

- Adjustable rollers: This allows you to change the thickness of the metal sheets. Most, if not all rolling mills will have this functionality.

- Gears: Gears help to ensure a consistent, even roll. Choosing a good gear ratio is essential so that you don’t struggle while trying to press tough metals such as gold. 1:5 / 1:6 gear ratio is ideal. This is not something you’ll have to worry about if you decide to go with a premium electric model.

- A sturdy frame: A rolling mill can be pretty heavy, so a sturdy frame is essential to prevent it from moving around or tipping over. In most cases, we all try to get light jewelry tools, so they’re easy to work with. For a rolling mill, it is pretty much the exact opposite. Without going off the chart with the weight, I suggest choosing a machine of no less than 40lbs.

Best Enntry-Level Rolling Mill for Jewelry Making

Gdrasuya10 Combination Rolling Mill for Jewelry Making

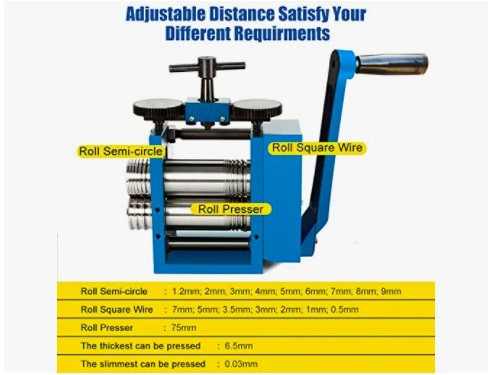

This Gdrasuya10 Jewelry Rolling Mill Machine is a 3-inch 75mm Manual Combination machine with a Gear Ratio of 1:6. It’s made of imported high hardness material DC 53 steel and is powder-coated for superior corrosion protection and appearance. The dual-speed motor enables the equipment to work steadily and quietly.

This combination Jewelry Rolling Mill Machine is a great way to create textures in metal. The machine has two smooth, hardened steel rolls polished and mounted in the housing parallel to each other. This allows you to easily create thinner gauges of sheet metal and wire while transferring textures to your metal. It is the best value for money and a great entry-level product.

Specifications

- Material: High-Quality Steel

- Slimmest press: 0.03mm

- Thickest press: 6.5mm

- Roll square: 7mm; 5mm; 3.5mm; 3mm; 2mm; 1mm; 0.5mm

- Roll presser: 75mm

- Roll semi-circle: 1.2mm; 2mm; 3mm; 4mm; 5mm; 6mm; 7mm; 8mm; 9mm

- Gear Ratio: 1:6

- Size: 18.91×14.97×7.88inch

- Weight: 48lbs

Check the Gdrasuya10 Rolling Mill prices on Amazon

Best Premium Rolling Mill for Jewelry Making

Durston 130mm Agile Combination Rolling Mill

The Durston Agile 130mm Combination Rolling Mill is perfect for jewelry makers looking for a high-quality, reliable rolling mill. With its self-lubricating bearings and maintenance-free design, this rolling mill is easy to use and provides a beautiful rolled finish every time. It’s also part of Durston’s award-winning range of products, available since 1961.

The all-new Agile 130 Rolling Mill is a special edition to the range of Durston rolling mills, coming from the same stable as the bestselling combination mills such as the DRM C130 RE. It is lighter by having thinner frames, but where the mill needs its strength, it’s entirely designed to support the load without compromising quality.

A traditional T-bar replaces the handwheel, and you’ll find five half rounds as part of the primary roller. The rolls are specially induction hardened to 64 RC. This is, in my opinion, the best premium manual rolling mill option.

Specifications

- Material: High-Quality Steel

- Slimmest press: 0.03mm

- Thickest press: 6mm

- Roll square: 11 square rolling groove including 7mm; 5mm; 3.5mm; 3mm; 2mm; 1mm; 0.5mm

- Roll presser: 50mm

- Roll semi-circle: 2mm, 3mm, 4mm, 5mm, 6mm

- Gear Ratio: 1:5

- Max wire capacity: 8mm

- Size: 20 x 13 x 18 inches

- Weight: 93 lbs

Check the Durston Agile Combination Rolling Mill prices on Amazon

Best Value Electric Rolling Mill for Jewelry Making

PepeTools Ultra Power Electric Combination Rolling Mill

This electric rolling mill is perfect for the jewelry artist looking to quickly texture metal. The machined aluminum base and direct-drive electric motor provide a smooth, easy-to-use experience, while the adjustable speed allows precise control. Japanese-made needle bearings in hardened steel cages make for a long-lasting tool, and the ductile steel frame ensures durability without adding weight.

The PepeTools Ultra Power Electric Rolling Mill is a combination rolling mill, capable of producing both flat and round wire. This machine produces up to 3/16″ (4.76mm) gauge flat wire and 1/8″ (3.18mm) gauge round wire. The ultra-fast motor can produce 0.5lb per minute flat wire or 2lbs per minute round wire with an 80% duty cycle at full load, this means you can roll more material faster than ever before! This product is the best electric rolling mill for seasoned or professional jewelry makers under $2500.

Specifications

- 1/2 HP 100:1 Reduction Gear Box

- Ductile Frame

- Aluminum Plate

- 1 – 17 RPM Forward &REVERSE

- Weight: 120lbs

- Size: 20″ wide x 10″ deep

- Whisper Quiet Motor

- It comes With Protective Guard for Saftey

- E-Stop for Safety

- Roller width – 130mm

- Roller diameter – 65mm

- Maximum opening – 5mm

- Flat area (+/- 0.01mm) – 66mm

- Square wire (+/- 0.01mm) : 1.0, 2.0, 3.0, 4.0 , 4.5, 5.0, 5.5, 6.0, 6.5

- Ring shank – half round ellipsis: 2.5 x 1:3 x 1.25 ; 4 x 1.5

- Capable of producing metal foil as thin as .001″

- All models are equipped with 4:1 reduction gearbox

Check the PepeTools Electric Combination Rolling Mill prices on Amazon

Wgwioo Jewelry Rolling Mill Machine

The Wgwioo Jewelry Rolling Mill Machine is a precision instrument perfect for cold rolling metal to produce thinner sheet metal and wire gauges. It consists of two smooth, hardened steel rolls mounted in the housing parallel to each other and powder coated for superior corrosion protection and appearance. This jewelry rolling mill machine is easy to use and efficient.

The rollers are easy to change for different applications, and the ‘v’ shaped grooves allow for a gradual reduction of item diameter. You can form different thicknesses of square section with this machine according to your requirements. Roller Width left up: 85mm, Middle roller width: 50mm, Maximum opening: 0-5mm, Square wire (+/-0.01mm): 1, 1.5, 2, 2.5, 3 ,4 , 6 , Round wire (+/-0.01mm): 2 ,3 , 4 , 5 , 6 , 8 . Combination Rolling Mill is ideal for jewelers and crafts-people to roll different kinds of metal into various shapes such as square or round wire (wire diameter from 0.2 mm to 4 mm), flat or round.

Specifications

- Material: Stainless alloy

- Weight: 50lbs

- Roller width left up: 85mm

- Middle roller width: 50mm

- Maximum opening: 0-5mm

- Square wire: 1mm,1.5mm, 2mm, 2.5mm, 3mm, 4mm, 6mm

- Round wire: 2mm, 3mm, 4mm, 5mm, 6mm, 8mm

- Combination round length shape: 120(mm)

- Round Diameter: 60(mm)

Check the Wgwioo Jewelry Rolling Mill Machine prices on Amazon

Rolling mill adjustable rollers

Rolling mills are handy tools for jewelry artists and goldsmiths. They allow for precise control of the thickness of metal sheets and wire. Adjustable rollers on a rolling mill enable the artist to form the metal to the desired thickness without having to heat the metal first. This is a huge time saver! Rolling mills are also great for texture: You can create exciting surface textures on your jewelry pieces by running different types of metal through the rollers.

You feed your sheet or wire through the rollers using a rolling mill. The top roller is called the “idle” roller and doesn’t move. The bottom roller is called the “drive” roller and turns. You can set the space between the rollers by adjusting the knob at the end of the mill. The smaller the space, the thicker your metal will be.

Most rolling mills come with two flat rollers, but some have grooved rollers for wire or texture plates for texture. You can usually buy extra rollers for your mill, depending on what you want to do with it.

Rolling mills Q&A

What are 4 of the standard roll configurations?

Four standard roll configurations are commonly used in rolling mills: flat, concave, convex, and camber. Each roll configuration offers its advantages and disadvantages and is suitable for different materials and applications.

Flat rolls are the simplest and most commonly used type of roll configuration. They are typically used for rolling out metals and plastic sheets. Flat rolls support the rolled material and can produce a relatively thin sheet. However, they can also cause the material to wrinkle or tear if rolled incorrectly.

Concave rolls are used for rolling out metals and plastic sheets as well. They offer good support for the material being rolled, but can also cause the material to Wrinkle or tear if it is not rolled correctly. Concave rolls are typically used for thicker or more challenging materials than flat rolls.

Convex rolls are used for rolling out metals and plastic sheets as well. They offer good support for the material being rolled, but can also cause the material to wrinkle or tear if it is not rolled correctly. Convex rolls are typically used for materials that are thinner or less challenging to roll out than concave rolls.

Camber rolls create a camber, or curve, in a metal or plastic sheet. They are typically used for materials that are difficult to roll out evenly with other roll configurations. Camber rolls can cause the material to wrinkle or tear if not used correctly.

What is 4 hi rolling mill?

4-hi rolling mill is a jewelry-making process that uses a four-roll mill to compress and shape metals. The four-roll mill is used to flatten and shape jewelry pieces and create textures and patterns on the jewelry. A 4-hi rolling mill is a versatile tool that can be used to create different looks for your jewelry. With this jewelry-making process, you can create beautiful, unique pieces that stand out from the rest.

What is cold rolling mill?

The steel is cooled to below its recrystallization temperature in a cold rolling mill before passing through rollers. This process increases the strength of the steel by causing the grains to deform, which in turn creates new grain boundaries. Cold rolling can be used to reduce the thickness of a material, as well as improve its surface finish.

What is a triple roller mill?

A triple roller mill is a machine that uses shear force created by three horizontally positioned rolls rotating in opposite directions and at different speeds relative to each other to mix, refine, disperse, or homogenize viscous materials fed into it.

The differential speed of the rolls creates shear force: the slowest roll rotates at a rate of 50 to 100 revolutions per minute (RPM), while the fastest roll rotates at 500 to 1,000 RPM. The gaps between the rolls are set based on the desired particle size; for example, particles smaller than 10 microns may be able to pass through a 0.5-millimeter gap. Triple roller mills are often used in ink and paint manufacturing and the production of ceramics and synthetic rubber.

Advantages of using a triple roller mill include:

- Can achieve extremely fine particle sizes

- Very high throughput rates (up to 100 kg per hour)

- Excellent for heat-sensitive materials, as there is minimal residence time at high temperatures

- Three rolls allow for three separate grinding mechanisms: compression, shear, and attrition – which can be adjusted to suit the material being processed.

Disadvantages of using a triple roller mill include:

- More expensive than other types of mills

- It can only be used for specific materials (i.e., those that are dense enough to flow between the rolls)

- Requires skilled operators to set up and adjust the machine.

What is a two-high rolling mill?

A two-high rolling mill is a type of mill that consists of two rollers that rotate in opposite directions. The purpose of a two-high rolling mill is to reduce the thickness of the workpiece in a single pass. In addition, a two-high rolling mill can be used to reduce the width of the workpiece by passing it through the rollers multiple times.

The advantages of using a two-high rolling mill include:

1. Increased Efficiency: A two-high rolling mill requires less time and effort to operate than a traditional rolling mill because a single motor drives both rollers.

2. Greater Capacity: A two-high rolling mill has a greater capacity than a traditional rolling mill because the workpiece can be passed through the rollers multiple times.

3. improved Quality: A two-high rolling mill produces a higher quality product than a traditional rolling mill because the rollers can apply more pressure to the workpiece.

4. Reduced Costs: A two-high rolling mill typically costs less to operate than a traditional rolling mill because the two-high rolling mill uses less energy and requires less maintenance.

Conclusion

If you’re serious about jewelry making with precious and semi-precious metals you will eventually need a rolling mill. In this article, I listed all the specific features I believe you should look for when selecting which product to purchase. I hope it is been useful.